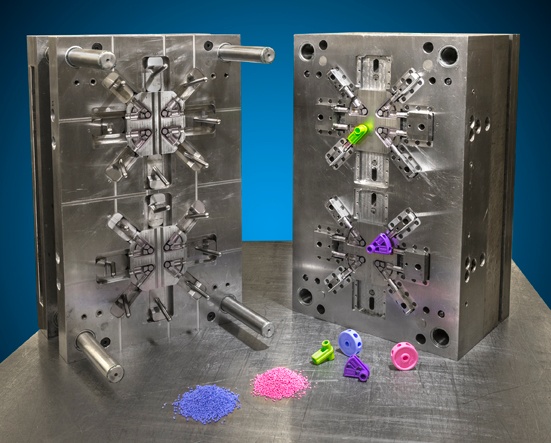

Although plastic injection molding has advanced significantly over the years, it's still based on the same standard principles it was years ago; today's technological developments have only further enhanced its versatility and reliability.

During plastic injection molding, plastic particles are melted down and injected into molds, which are chilled via water or a coolant that allows the plastic to harden. Once it has hardened, it is ejected from the mold and ready for use.