While plastic injection molders will help you determine the size of the machine needed to get the best result, a project designer or engineer will get a good estimate based on some basic information. By knowing approximately what size machine will be required, you can better source a plastic injection molder that will meet your needs.

With over 16,000 injection molding and plastic manufacturing facilities in the United States, there is no shortage of companies to choose from. When choosing a provider, many factors should be taken into consideration, including capabilities, quality assurance, cost, company reputation, and delivery time. Finding the right plastic injection molder to fit your needs may seem daunting, but determining your volume requirements first and foremost — and how they may shift over time — will help narrow down your options.

What Exactly is Turnkey Manufacturing?

Turnkey manufacturing is a full-service manufacturing process in which one company sees through all aspects of a client’s project — from design to tooling to quality control to packing and shipping, leaving the customer with a finished, ready-to-use product.

There are numerous benefits to turnkey manufacturing, from cost savings to streamlined communication. Below, we’ll explore some of these advantages.

Plastic injection molding has a language all it’s own and with so many unique terms it can be difficult to learn the language. We put together a list of the top terms to know when discussing plastic injection molding, mold parts, materials, and problems. We hope you find this to be a useful resource.

When working with any manufacturing process, a number of defects unique to that process commonly occur. This is true across many processes and industries, including injection molding and high volume injection molding.

As we have previously discussed on this blog, there are several common injecting molding defects; however, an injection molder who is vigilant about quality, like our team at The Rodon Group, will be able to manage these injection molding defects, minimizing or eliminating them all together.

At Rodon, we manufacture billions of parts every year and have done so since 1956. We are proud to have earned a reputation for being one of the best in the industry, offering high-quality, low-cost solutions. When businesses have a need for high volume, high tolerance, intricate parts, they turn to custom plastic injection molding.

The number of polymer compounds has grown over the past 20 years. As a result, plastics are being used in more applications than ever before. These materials are gaining a reputation for strength and endurance. Combine these improvements with the advantages of corrosion resistance and aesthetic appeal and plastics are taking center stage in the manufacturing of many consumer and industrial components. Due to their versatility, strength and light weight characteristics, plastics are also taking a larger role in the transportation, medical and construction industries.

Here are five requirements to keep in mind when choosing your resin:

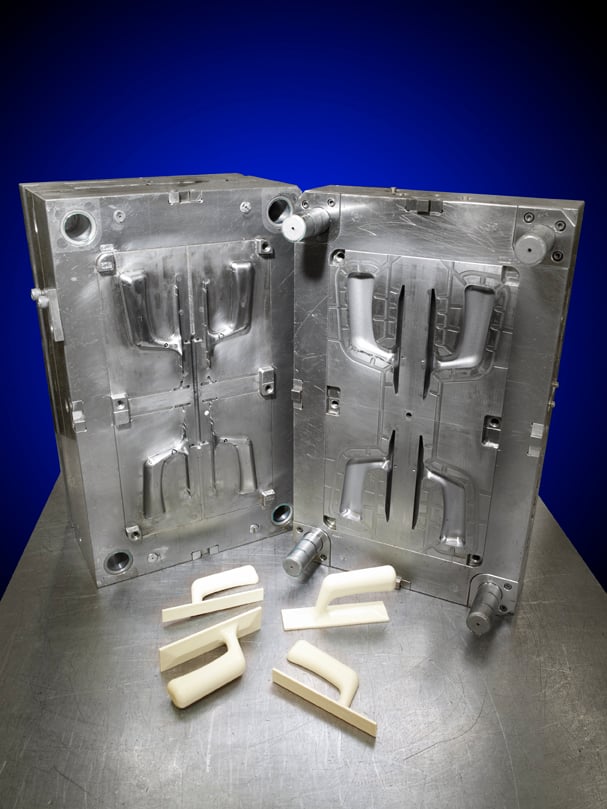

Before you can manufacture a plastic part you need to have a solid design in place. Once done, you can build an injection mold to meet the product specifications.

The role of the Design Engineer is critical in this process. They assess the part design and make modifications and recommendations based on key product requirements including product usage and function. The engineer will need to know:

- How will the part be used? Is it a standalone product or a component of a larger assembly?

- What are the dimensional and tensile requirements?

- Does the part need to withstand elements, pressure, chemicals?

A plastic injection mold design is built with these criteria in mind. Mold cavities, vents and gate placement will vary based not only on the part design but the type of resin as well. Taking all of these manufacturing factors into account is a challenging task and one that requires a strong knowledge base, not only of mold design but the injection molding process as well.

Our website is frequently visited by product designers, engineers and purchasing agents who are looking for information on plastic injection molding. With this in mind, we created a series of "Basics 101" type articles that are developed to give our readers a better understanding of the presses, processes and pitfalls in our industry.

We begin our series with information on the basics of plastic injection molding presses. We hope you find this information useful. If you have specific questions, please do not hesitate to contact us.

Injection Press Basics

While plastic injection molders will help you determine the size of the machine needed to get the best result, a project designer or engineer can get a good estimate based on some basic information. By knowing approximately what size machine will be required, you can better source a plastic injection molder that will meet your needs.