The success and precision of a part depends on the quality of its mold, but building a reliable, long-lasting tool can take a considerable amount of time — and requires a great deal of accuracy. Also, molds are often one the largest capital investments in a project, so it’s critical that tooling is built right the first time around. This is particularly important in high-volume injection molding projects, where molds can be extremely complex.

While plastic injection molders will help you determine the size of the machine needed to get the best result, a project designer or engineer will get a good estimate based on some basic information. By knowing approximately what size machine will be required, you can better source a plastic injection molder that will meet your needs.

Our website is frequently visited by product designers, engineers and purchasing agents who are looking for information on plastic injection molding. With this in mind, we created a series of "Basics 101" type articles that are developed to give our readers a better understanding of the presses, processes and pitfalls in our industry.

We begin our series with information on the basics of plastic injection molding presses. We hope you find this information useful. If you have specific questions, please do not hesitate to contact us.

Injection Press Basics

While plastic injection molders will help you determine the size of the machine needed to get the best result, a project designer or engineer can get a good estimate based on some basic information. By knowing approximately what size machine will be required, you can better source a plastic injection molder that will meet your needs.

A common question for designers and engineers is “How much will a plastic injection mold cost?” It makes sense. Injection molds represent the greatest expense in upfront production costs. And, there are many factors that go into determining the cost. With any custom injection molding project, your injection molder will be able to give you the final price tag.

In this article, we will review the variables that can impact the cost so that you can be better informed in making a mold purchasing decision.

Seven hundred pounds of hardened stainless steel. That’s the average weight of an injection mold. Some can weigh over a ton, some just a few hundred pounds, but any way you slice it, you certainly wouldn’t want one to fall on your foot.

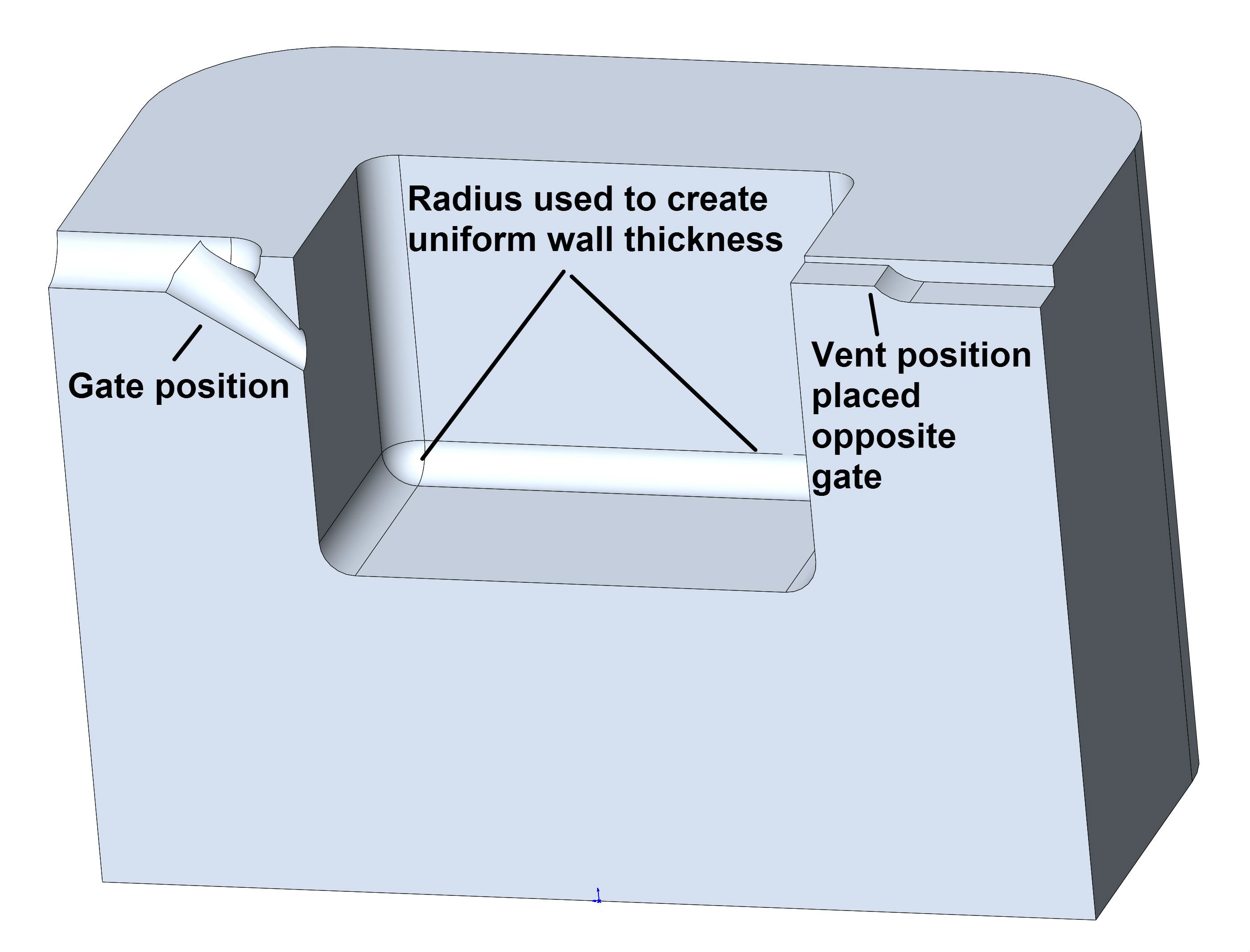

There are four key factors that go into making a high-quality plastic injection molded part: part design, tool building, material selection and manufacturing.

In this article, we will start at the beginning of the process, with the part design.

The process of plastic injection molding is designed to produce precision parts at a low cost. The part design must be developed to maximize the efficiency inherent in high-volume molding. With the right design, parts can be made consistently and with quality. Without a good design, costly processing mistakes can be made.

The Rodon Group was busy in 2014 providing information to help companies make better decisions about their plastic manufacturing. With nearly 80 articles on our blog post, we covered a lot of territory.

So, we thought we would take a moment to highlight our top sellers; the articles that got the greatest response from our readers.

Plastic Injection Molds and Presses

Every plastic part starts in a mold. Molds are classified into two main types, cold runner and hot runner. Each has its advantages and disadvantages. Your plastic injection molder will be able to give you the costs and benefits of using these different systems. However, by understanding the key differences of these technologies, you can have a more educated discussion on the type of mold that would best fit your project.

Our website is frequently visited by product designers, engineers and purchasing agents who are looking for information on plastic injection molding. With this in mind, we have created a new series of articles that are developed to give our readers a better understanding of the presses, processes and pitfalls in our industry.