In the wake of COVID-19, hospitals, labs, and research centers were pushed to their limits. Facing a shortage of PPE and other supplies, many facilities were forced to find innovative solutions to meet their growing needs. For Fox Chase Cancer Center, a research hospital in Philadelphia, that meant connecting with The Rodon Group to develop and manufacture new nasal and throat swabs to test for the virus.

In the wake of COVID-19, hospitals, labs, and research centers were pushed to their limits. Facing a shortage of PPE and other supplies, many facilities were forced to find innovative solutions to meet their growing needs. For Fox Chase Cancer Center, a research hospital in Philadelphia, that meant connecting with The Rodon Group to develop and manufacture new nasal and throat swabs to test for the virus.

Project Overview

When Fox Chase started testing patients for COVID-19, they struggled to find enough swabs. Joel Glickman, chairman of The Rodon Group and inventor of the K'NEX building system, had been a patient at that hospital; his doctor, Eric Horowitz, reached out to Glickman to see if we might be able to help the hospital meet their demand for nasal swabs.

Glickman agreed to the partnership, and in the end, The Rodon Group produced a swab that has been registered by the FDA. For the next five years, we will supply Temple University Health System with all the swabs they need.

Project Challenges

The first challenge was meeting FDA regulations. Fortunately, a couple of key contacts at Fox Chase connected Rodon with experts who helped us meet the sanitation and packaging requirements.

.png?width=518&name=Rodon%E2%80%93Quote%20Box-Swab%20Case%20Study%20(1).png) From there, the challenge was meeting a tight timeframe with an essential product, but Rodon has long been focused on offering rapid turnaround times for their clients. This was no exception, even as we worked to develop the capabilities to produce a product we’d never produced before.

From there, the challenge was meeting a tight timeframe with an essential product, but Rodon has long been focused on offering rapid turnaround times for their clients. This was no exception, even as we worked to develop the capabilities to produce a product we’d never produced before.

Project Solution

In an ISO 9001:2015 certified facility, we put our turnkey manufacturing capabilities to work using medical-grade materials. As a local U.S. manufacturer, we keep costs and lead times low while streamlining the entire production process.

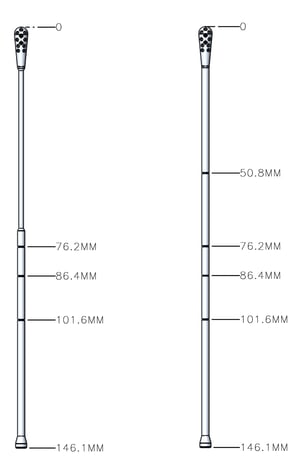

This isn't just another swab—it’s a better one, featuring a new fluid trap-tip design that allows for better collection and release of the sample. A simple experiment within the hospital, where patients were tested with both the old swab and the Rodon swab, demonstrated the new product’s superiority.

“We came up with a quick study to test people who were already getting swabbed. These patients would be swabbed twice, first with the one Fox Chase had been using and then with the new test swab. It turned out that the one Joel designed actually worked even better than the one we had. It’s been just one of many partnerships that has worked out for the common good of people,” said Horwitz.

Highlights of This Plastic Injection Molding Project

At The Rodon Group, we applied our turnkey manufacturing solutions, plastic injection molding capabilities, and high-volume production capabilities to produce a swab that meets the stringent requirements for use in medical, diagnostic, and laboratory settings. The swab has been FDA registered. Our Quality Management System is certified to ISO 13485:2016.

As a U.S. manufacturer, we can offer turnaround times of just a few weeks. This is a new production process for us that required new equipment, but we’re expecting to produce 40-50 million swabs per year with that equipment in place. We’re proud to do our part to aid the fight against the pandemic, and we’re pleased to be partnered with a hospital within our community to do it.

Contact us to learn more about our partnership with Fox Chase.