Importance of Plastic Injection Molding in the Food and Beverage Industry

The food and beverage industry is heavily regulated to ensure containers, industrial process components, and other parts comply with safety standards. As such, manufacturers use food-grade plastic materials for part design and construction, including plastic injection molding. Plastic injection processes can create complex, identical goods with a low risk of error. This makes plastic an increasingly popular alternative to metal, with specific advantages regarding food and beverage safety.

Industry Regulations/Certifications

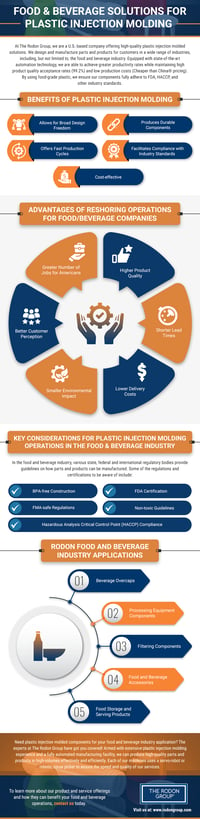

Several regulatory bodies govern what food and beverage manufacturers—as well as plastic injection molding companies—need to be aware of to stay compliant. Some of the requirements and regulatory institutions to keep in mind include:

- BPA-free construction

- FDA certification

- FMA-safe regulations

- GMA-SAFE

- ISO 13485 cleanroom certification

- ISO 9001:2015

- Hazardous Analysis Critical Control Point (HACCP) compliance

- Non-toxic guidelines

The Rodon Group ensures compliance with all applicable regulations and compliance standards. In particular, all food-grade parts are produced with HACCP compliance in mind. These standards focus on identifying, controlling, and eradicating all chemical, microbiological, and physical hazards. This focus minimizes the risk of food-borne diseases. It also increases consumer confidence in the safety, and therefore value, of our food-grade plastic components. We adhere to these standards for both final food and beverage products and the equipment used to manufacture them.

Food and Beverage Industry Resins and Grades

Food-grade plastics are those that stay inert and nonreactive throughout their life cycle. Because food-grade materials come in direct contact with food and (for parts such as straws and utensils) people, stable materials are essential. As such, these materials must be durable, even under these conditions:

- Chemical exposure, including both the food products themselves and any cleaning chemicals or ambient environmental factors

- Color additives must not degrade or contaminate the food

- Temperatures, including environmental heat, cooking, and processing heat, cool-climate control, and extremely low temperatures

- UV radiation from both indoor and outdoor exposure

Based on the project's application, one of the many popular food-grade materials may be chosen to complete it, including:

- HDPE plastic: This stiff, hard material is durable and resistant to chemicals. It's commonly used for manufacturing containers.

- LDPE plastic: This thin matte plastic can form films, plastic wraps, and flexible packaging. It's non-toxic and odorless.

- PC plastic: This material is safe for making containers for fluids, especially bottles.

- PET plastic: This is popular for bottles and other semi-rigid containers that need to hold their shape under moderate pressure levels.

- PP plastic: This is non-toxic and stays stable in low and high temperatures. It's commonly used for making bags, boxes, and container components or utensils.

- PS plastic: This plastic resists damage from low temperatures. It's commonly used for snack boxes, processed food boxes, and more.

Food and Beverage Applications

Plastics are increasingly popular both for containers and devices that reach consumers and parts used throughout the food production process. Food and beverage manufacturers frequently turn to The Rodon Group for assistance with food-grade injection molding services for packaging and processing applications, including:

- Beverage Overcaps: Custom-designed caps for beverage containers.

- Processing Equipment Components: Reduce breakage throughout processing stages.

- Beverage Filtering Components: Can be submerged in or regularly interact with beverage fluids with no risk of degradation or contamination.

- Food and Beverage Components: This includes food and beverage containers and straws.

- Food Storage and Serving: Temperature-resistant plastics create storage, protective wrappings, and larger containers for individually wrapped products.

Advantage of Plastic Injection Molding

Some of the advantages of using plastic injection molding include:

- Custom containers

- Cost-effectiveness

- Durability

- Fast production cycles

- Resistance to chemicals and UV radiation

- Compliance with GMA-SAFE and FDA standards and ISO certification

Benefits of a Custom Turnkey Approach

At The Rodon Group, we offer comprehensive plastic part services for our food and beverage customers. Our turnkey process includes:

- Designing of custom molds

- Partnering with reputable resin suppliers

- Producing molds constructed from stainless steel mold bases and cavities

- Manufacturing the finished plastic goods at our fully automated facility

- Managing process with two-step quality inspections

As part of our production services, we maintain high quality and sanitation standards from start to finish.

The Rodon Group Capabilities for Food and Beverage

We have a fully automated facility that can produce high-volume runs quickly. Each machine has a servo-robot or robotic sprue picker to guarantee the quality and speed of our services. Contact us today to learn more about our capabilities or to project.

If you are interested in learning more about our food and beverage mold manufacturing capabilities, visit our comprehensive case studies page to view examples of our past projects.