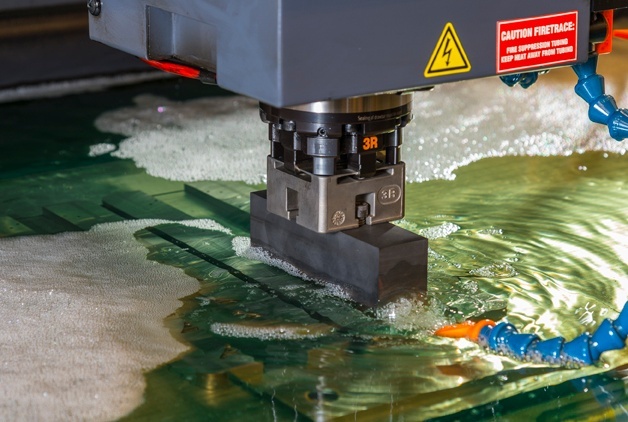

Ever since its introduction in the late 19th century, plastic injection molding has revolutionized the way we create plastic products. Although the technology has evolved significantly over the years, many injection molds today still fall into two main categories: hot runner and cold runner systems. Each of these systems has their own benefits and limitations which make them better suited for specific applications.

Understanding the differences between these technologies can help you have a more productive and informed discussion with your plastic injection specialist to determine the most feasible option for your unique application.