As the COVID-19 pandemic continues to devastate global supply chains, many businesses have begun reshoring their operations. This trend is particularly prevalent in manufacturing, although reshoring rates have started to rise throughout the industrial sector in recent weeks. In fact, the Thomas Industrial Survey for April found that 64% of manufacturers are now considering reshoring, compared to only 54% who were thinking about reshoring in March.

Advancements in plastic injection molding technology allow manufacturers greater flexibility and sophistication in part design. At The Rodon Group, we are continually incorporating the newest technologies to remain on the cutting-edge of molding techniques in all sectors. This commitment to growth and innovation has allowed us to continue providing the highest-quality products to our customers.

When looking for a manufacturer that will provide you with quality, savings, and a quick turnaround, it’s essential to consider the location of your facility. While many companies are moving overseas in search of cheaper production and labor costs, it often pays to keep your company based right here in the United States. In fact, there are numerous benefits to choosing a manufacturer based in the United States over those found abroad––, especially in the long run. Below, we discuss seven of the main advantages.

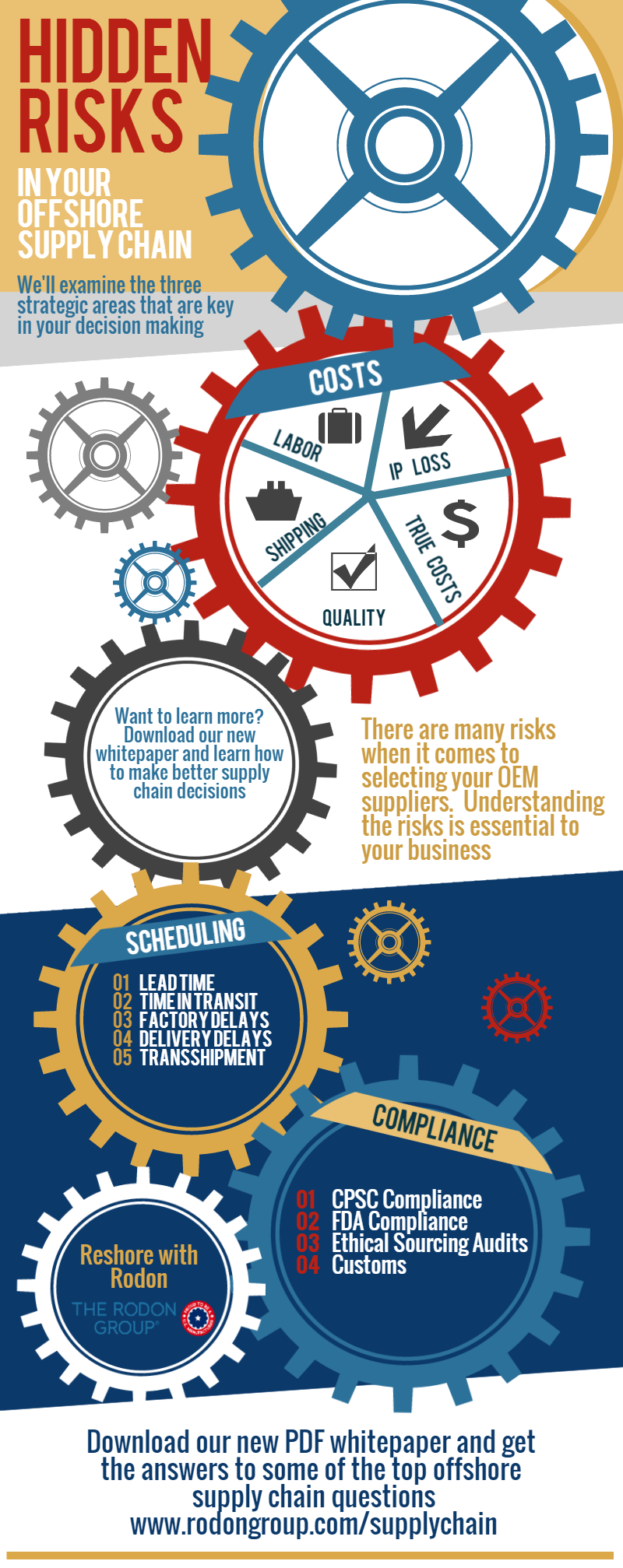

There are many risks involved in selecting an OEM suppliers. Understanding them is essential to running a successful business. In our white paper "Hidden Risks in Your Offshore Supply Chain", we’ll examine three strategic areas to include in your supplier selection process: Cost, Scheduling, and Compliance.

Cost

Cost is not just the final price you pay for a part. Cost also includes shipping, time to market delays, quality control checks as well as labor. Cheap foreign labor is becoming more expensive. Offshore suppliers face a more demanding workforce. And, today’s consumers are demanding that suppliers provide improved working conditions and pay. All of this is driving up the unit cost of goods sold.

American vs. Overseas Manufacturing

There are many risks when it comes to selecting OEM suppliers. Understanding them is essential to running a successful business. In this article, we’ll examine the factors that impact scheduling and time-to-market when using an offshore supplier.

There are many factors that impact the total cost of goods purchased. On the surface, some offshore suppliers may seem cheaper. However, the true delivered cost is impacted by many variables. Using this overview, you should be able to better compare all of your supplier choices.

American Manufacturing and Products

This article written by the Reshoring Initiative Editorial Team originally appeared on the Reshore Now blog on October 15, 2014

It is no secret that the last decade has brought a surge in demand for products made in the USA. But it was only recently we realized how much the “Buy American” movement has evolved.

In a recent survey conducted by American Certified, 1500 people across the nation were asked the question, “Other than price/ quality, what factor is most important to you when purchasing a product?”