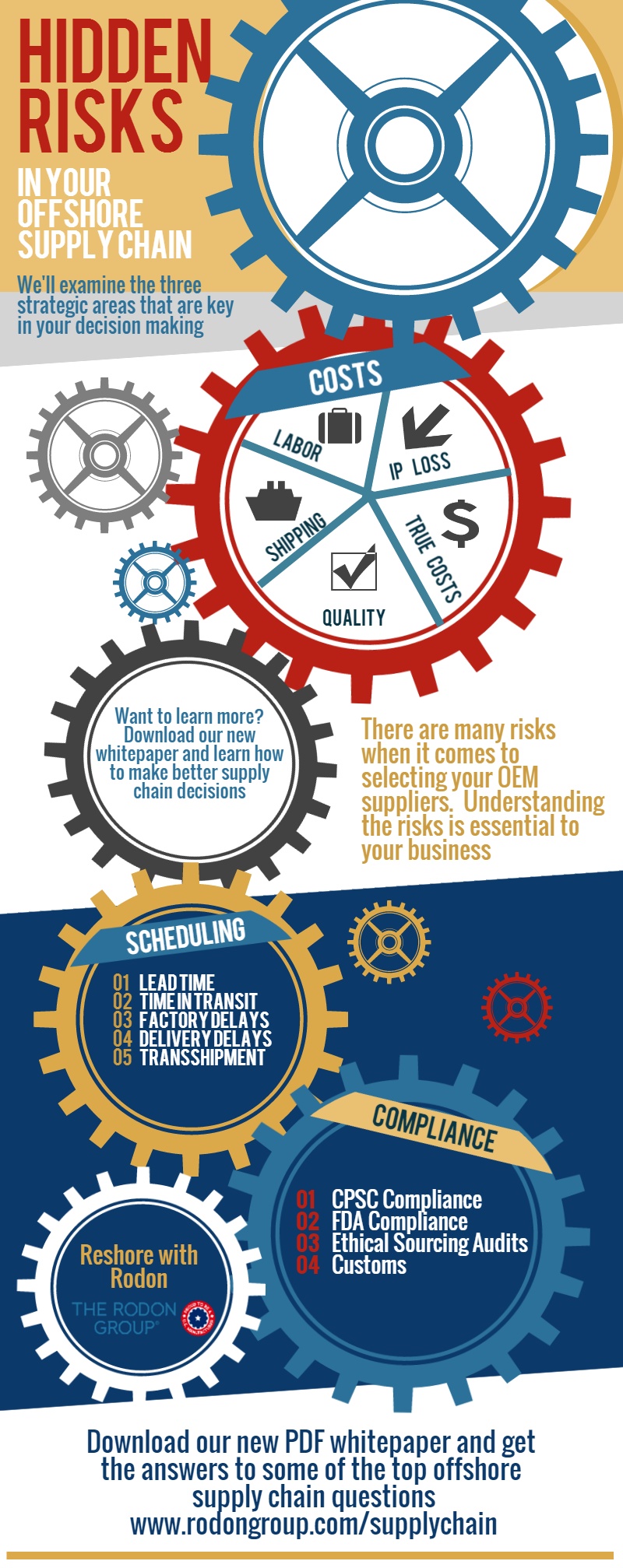

There are many risks involved in selecting an OEM suppliers. Understanding them is essential to running a successful business. In our white paper "Hidden Risks in Your Offshore Supply Chain", we’ll examine three strategic areas to include in your supplier selection process: Cost, Scheduling, and Compliance.

Cost

Cost is not just the final price you pay for a part. Cost also includes shipping, time to market delays, quality control checks as well as labor. Cheap foreign labor is becoming more expensive. Offshore suppliers face a more demanding workforce. And, today’s consumers are demanding that suppliers provide improved working conditions and pay. All of this is driving up the unit cost of goods sold.

Scheduling

Just as important as the cost of goods, is scheduling. Scheduling is a tricky area where small changes can have a big downstream impact. If a supplier is far removed from the end consumer, additional time should be built into the delivery schedule to compensate for various factors. Additional lead time will help manage inventory levels to accommodate customer needs. Time in transit should include not only the time to port, but from port to final destination. It’s wise to have a “cushion” to allow for any unforeseen factory delays or customs snags.

Compliance

Lastly, businesses must consider compliance requirements. While not all products require a lot of scrutiny to pass government requirements, there are many classifications of goods that must be well documented. Remember the lead paint found in children’s toys several years ago? This product flaw sparked additional oversight and inspections for an array of consumer goods. Obviously, food, drugs and anything for children are on the top of the list. However, component parts and materials in products might need to pass inspection as well. Many foreign suppliers are not aware of our government’s requirements, or they may find ways to work around the regulations. It is the responsibility of the importing company to guarantee their goods meet all the guidelines. Failure to do so could end in customs confiscation. Worse case, the importing company may be asked to destroy the shipment.

In the infographic below, we highlight the three primary areas we focus on throughout the white paper and that should be included in your strategic decision-making process. When you take all of the factors into account that can impact the cost, scheduling and quality of your manufactured part, you can make a more informed decision about your supplier selection.

Download the whitepaper at www.rodongroup.com/supplychain

Comments