Many companies utilize offshore manufacturing to save on labor costs and raw materials. When it comes to fabricating plastic injection molds, those savings may seem significant; however, offshore manufacturing often comes with many drawbacks such as shipping delays and low product quality. These issues quickly eliminate any cost benefits associated with Chinese injection molds as they often result in the need for reworked parts.

As the COVID-19 pandemic continues to devastate global supply chains, many businesses have begun reshoring their operations. This trend is particularly prevalent in manufacturing, although reshoring rates have started to rise throughout the industrial sector in recent weeks. In fact, the Thomas Industrial Survey for April found that 64% of manufacturers are now considering reshoring, compared to only 54% who were thinking about reshoring in March.

When looking for a manufacturer that will provide you with quality, savings, and a quick turnaround, it’s essential to consider the location of your facility. While many companies are moving overseas in search of cheaper production and labor costs, it often pays to keep your company based right here in the United States. In fact, there are numerous benefits to choosing a manufacturer based in the United States over those found abroad––, especially in the long run. Below, we discuss seven of the main advantages.

Last week we featured a blog post by guest author Benn Lamm focusing on how to look for American made products. He offered several great tips on how to determine where a product was made while you're looking for American-made products.

American Manufacturing and Products

With Independence day approaching, we wanted to provide some helpful tips to use when looking for American-made products. Below is a guest post from Benjamin Lamm at Label Land, LLC, an American clothing label company located in NJ. Benjamin is a content specialist, writer, musician, father and husband (not necessarily in that order!)

American manufacturing is alive and well in Pennsylvania. When Secretary Clinton and other key policy makers visited us a few weeks ago, we were reminded of the important role we play, not only as a U.S. manufacturer since 1956, but first and foremost as a Pennsylvania manufacturer.

Pennsylvania has a long history of industrial and manufacturing firsts. Scranton, in the northeastern part of the state was the first city in America to be electrified. Titusville, Pennsylvania was the birthplace of the oil industry. Iron production first began in this state in 1716 and within 100 years coal was fueling industrial growth.

American Manufacturing and Products

This article written by Adam Robinson originally appeared on the Cerasis blog on October 28, 2015

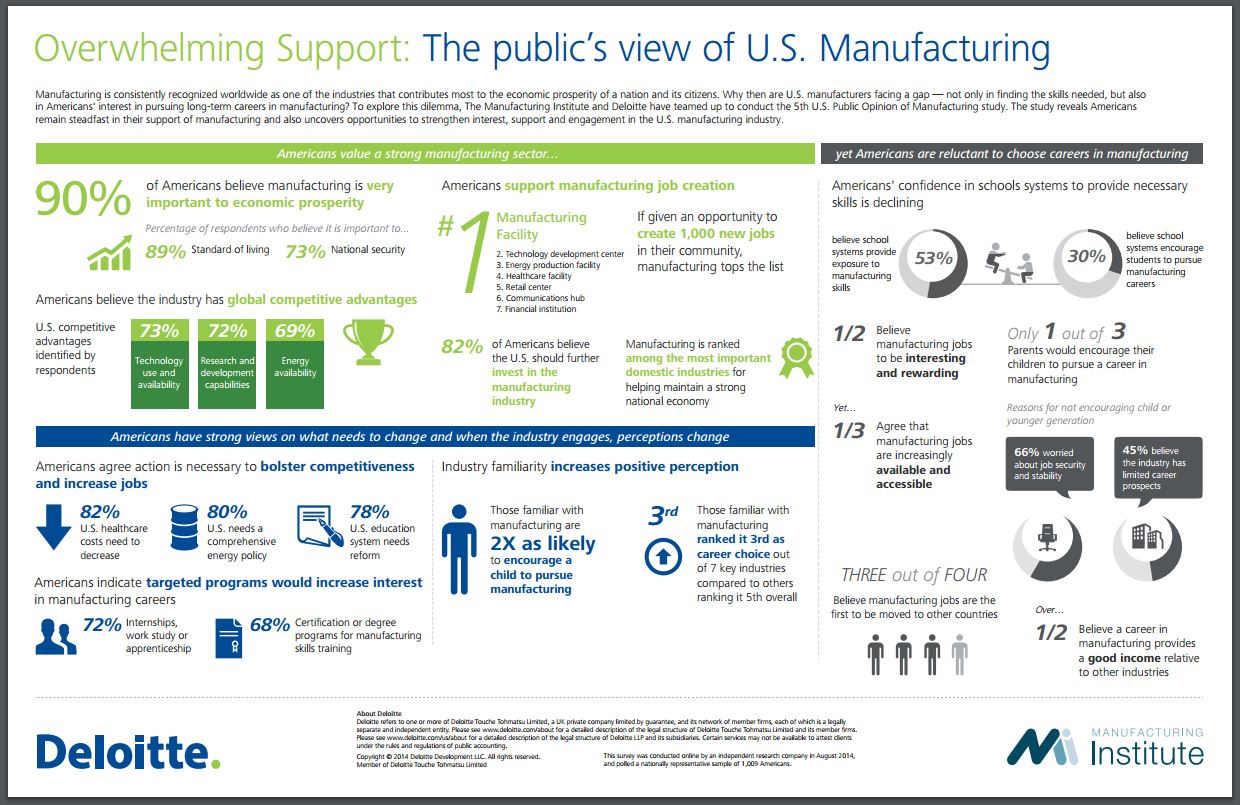

In today's post, we feature a great infographic below from a joint report by Deloitte Manufacturing and the Manufacturing Institute. Before featuring this information so that manufacturers understand how the public views them, let's first go through a brief history of the American Manufacturing Industry by highlighting some moments & inventions that changed the way of life as we know it.

For years, products made in the United States have been considered to be more expensive than products made overseas. Manufacturing was cheaper outside of the US, and it was easier to find the low-paid labor needed to keep factories running. In 2004, each manufacturing dollar in the United States cost only 86.5 cents to produce in China, leaving a much wider margin for profit for goods made overseas. According to The Boston Consulting Group, by 2014, that number had changed substantially: each manufacturing dollar in the United States costs 95.6 cents to manufacture in China. The trend suggests that the gap between those numbers can only close further. As a result, a growing number of American companies are reversing the trend and bringing manufacturing back to the United States.

Advances in the development of new and improved polymers have led many engineers and product designers to re-think their use of more traditional materials in the manufacturing process. Parts once thought of as impossible to create using plastic, are now being designed with polymers at a higher rate than ever before.

Plastics have historically offered many advantages over other materials, particularly metal. Plastic parts are lighter and afford more design flexibility. They tend to be less expensive than metals and need little if any finishing or additional assembly. And today's innovative polymers are developed with the environment in mind. Using bio-based solutions and easily compostable materials, the goal is to leave as little impact on the planet as possible.