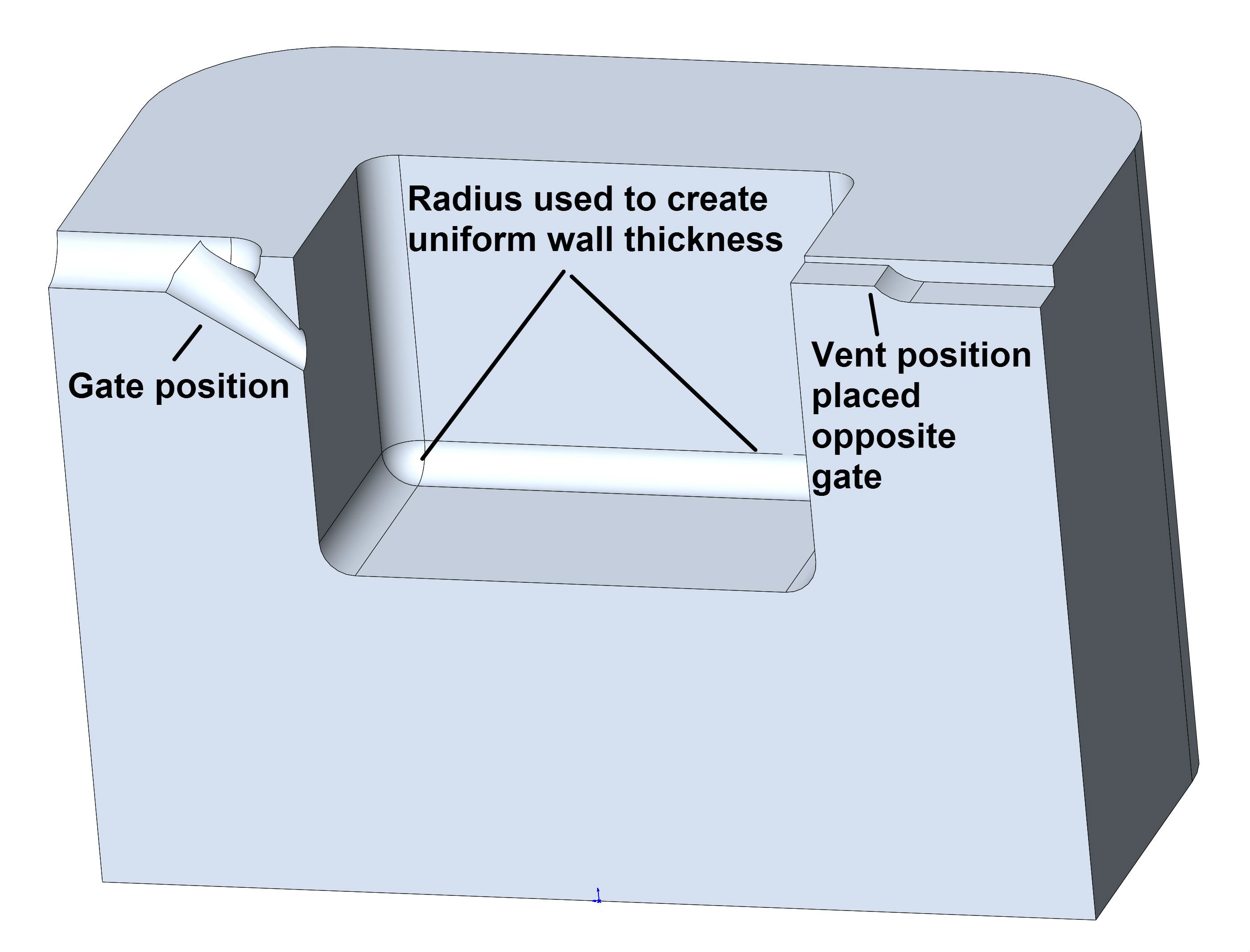

There are four key factors that go into making a high-quality plastic injection molded part: part design, tool building, material selection and manufacturing.

In this article, we will start at the beginning of the process, with the part design.

The process of plastic injection molding is designed to produce precision parts at a low cost. The part design must be developed to maximize the efficiency inherent in high-volume molding. With the right design, parts can be made consistently and with quality. Without a good design, costly processing mistakes can be made.