Excerpts from a report by an advisory council of Team Pennsylvania Foundation

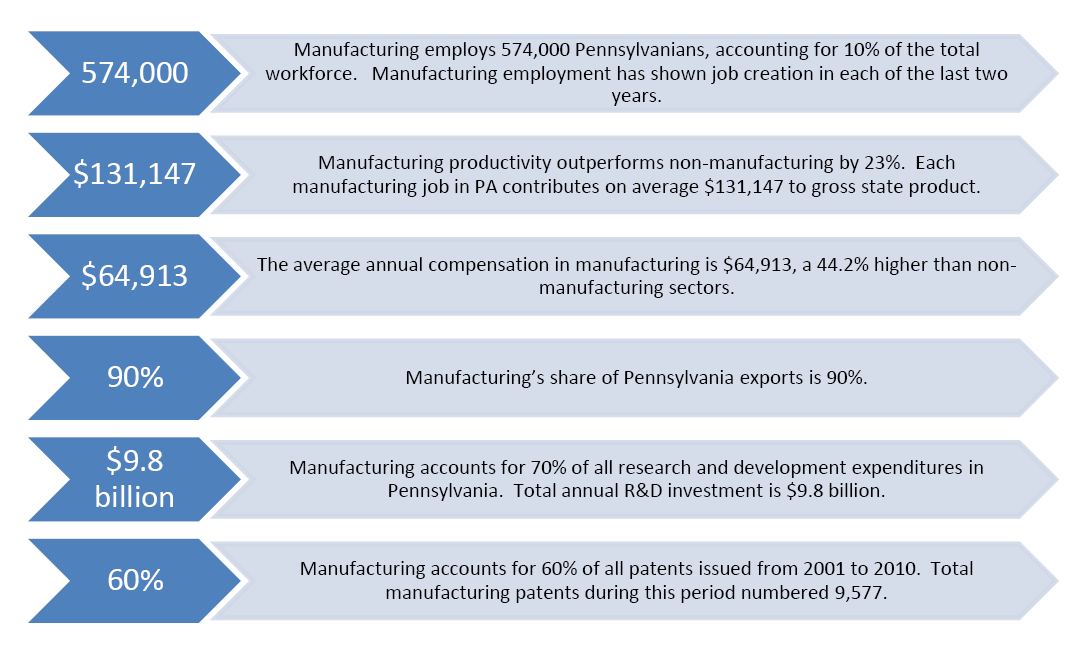

Following the challenges brought by the Great Recession, the manufacturing sector in Pennsylvania is undergoing a renaissance. With gross state product (GSP) now reaching $71 billion, manufacturers in Pennsylvania account for over 12% of the total output in the commonwealth1. Pennsylvania remains the 6th largest manufacturing state in the United States (utilizing GSP as a benchmark). Pennsylvania outranks other historically industrial states including Michigan, Indiana, New York and New Jersey2. Pennsylvania is now producing more products than at any time in its history. For each of the last two years manufacturing employment has increased significantly and in 2011 alone 12,100 new jobs were created3. While employment continues to grow, the sector continues to experience measurable leaps in productivity driven by technology adoption and process innovation. Manufacturing productivity outpaces all other sectors with a staggering 259% increase over the last 40 years4.

With nearly 15,000 manufacturing establishments across the commonwealth, the outlook is bright for continued growth. Pennsylvania firms are building upon a proud heritage in manufacturing and have demonstrated new and creative approaches of integrating innovation into both products and processes. Recognizing the dynamics of the global marketplace, Pennsylvania hosts scores of multinational facilities exporting at record levels around the world accounting for more than 90% of all Pennsylvania exports.