Both injection molding and 3D printing are additive manufacturing processes that create highly complex parts using near-identical product runs. Manufacturers can choose from a broad selection of plastics and thermoplastic materials to perform either process, but there are a few applications where injection molding or 3D printing is preferred. If you're choosing which technique to use for your organization, consider the following side-by-side comparison.

Plastic Injection Molding

Injection molding is a fast production process that injects a molten plastic or other build material into a pre-made mold, where the material hardens and cools into shape. Once the build material is fully set, the parts can be removed and finished. Every mold typically lasts for thousands or tens of thousands of production cycles.

Advantages

Injection molding processes offer several benefits, including:

Low Unit Costs

After the mold has been built, replicating the prototype is simple: The molten build material is injected into the mold at high pressure, and then the cast product is collected and finished as needed. Plastic injection molding uses raw resources efficiently compared to other manufacturing processes and doesn’t produce a significant amount of waste. The simplicity and replicability of injection molding make it relatively cost-effective. Larger production sizes see the lowest per-unit expenses.

Product Quality

Injection molding brings intricate designs to life with exceptional precision. Every millimeter of the mold is fully filled to prevent air bubbles, segmentation, or other design flaws. A product made with injection molding is complete without the need for seams or assembly, so the surfaces will be smooth and have functional integrity. This produces more visually appealing and reliable parts compared to those that are made with 3D printing.

Speed

Depending on the type of plastic used, injection molded products can set in a matter of seconds. Many plastics don’t need to be finished, which helps further cut production time. Most mold plates can also hold more than one piece, multiplying the speed of production. Combined with the automated nature of injection molding, manufacturers can create hundreds of thousands of pieces a day and easily sort their products into batches.

Disadvantages

Injection molding has a few disadvantages, including:

Upfront Investment in the Mold

A significant portion of the cost goes toward creating the mold. If the product has a short lifecycle or low demand, investing in a long-lasting mold may be more expensive than using a 3D printer.

Modification Limits

Once the mold is created, it can’t be modified without editing the product design and recasting the mold. If you’re still testing prototype developments, it may be better to use a different production method until the design is finalized.

Applications

Some of the most common applications for injection molding include:

- High-volume production runs.

- Quality plastic products that require precision and consistency.

- Projects with long turnaround times.

- Any parts ranging from small and complex to large and simple.

We encourage readers to do some research on the full capabilities and benefits of large-scale injection molding. Our Introduction to Plastic Injection Molding eBook is an excellent resource to familiarize readers with injection molding in the 21st century.

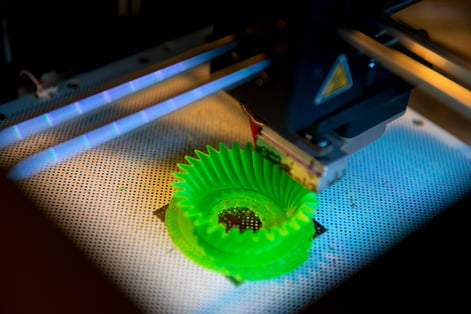

3D Printing

3D printing uses computer-aided design (CAD) files to build three-dimensional parts layer by layer. The 3D printer uses a filament to create vertical layers that stack on top of each other; it creates one product at a time.

Advantages

Advantages

3D printing offers several benefits over plastic injection molding, including:

Low Initial Cost

3D printing doesn't use specialized dies. Once the design file is complete, the printer can create one or hundreds of the complete product at the same cost per unit.

Flexibility

Because it uses a computer file instead of a mold, 3D printers can easily accommodate changes to the product design. This is ideal for prototyping when your team tests different designs and stages.

Disadvantages

3D printing can complicate the process in some situations and has the following drawbacks:

Technical Issues

3D printing is a developing science. The software and hardware occasionally malfunction, potentially leading to errors and low structural integrity that must be identified during the quality assurance process.

Speed

3D printing builds layer by layer, one item at a time. It's most effective for orders with several hundred units or less.

Product Quality

3D printing can create visible ridges and structural faults during manufacturing that typically don’t occur with plastic injection molding.

Applications

It’s common to use 3D printing for:

- Prototyping and testing products.

- Small production runs

- Customized products.

- Products that are frequently modified or updated.

Choose the Rodon Group for Injection Molding and 3D Printing

The Rodon Group has specialized in high-quality manufacturing solutions for over 60 years and can deliver the results you need to suit every application. We also maintain several of 3D printers for prototyping so that we may better assist you in designing your parts for full scale, injection molded production. Contact us today to learn more about our capabilities.

Comments