There are many factors that impact the total cost of goods purchased. On the surface, some offshore suppliers may seem cheaper. However, the true delivered cost is impacted by many variables. Using this overview, you should be able to better compare all of your supplier choices.

There are four key factors that go into making a high-quality plastic injection molded part: part design, tool building, material selection and manufacturing.

In this article, we will start at the beginning of the process, with the part design.

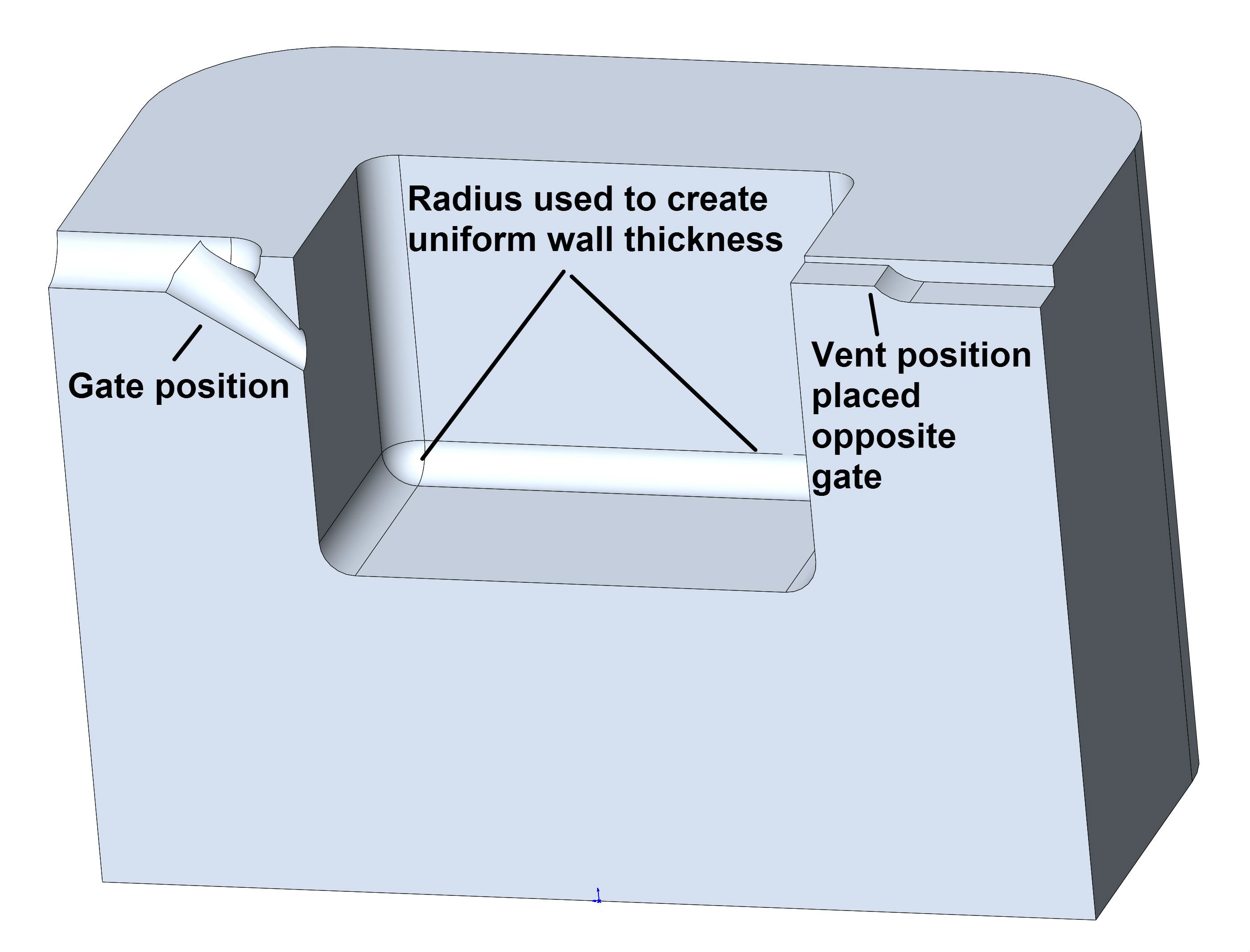

The process of plastic injection molding is designed to produce precision parts at a low cost. The part design must be developed to maximize the efficiency inherent in high-volume molding. With the right design, parts can be made consistently and with quality. Without a good design, costly processing mistakes can be made.

This article written by Adam Robinson, Marketing Manager at Cerasis, originally appeared on the Cerasis blog on March 6, 2015

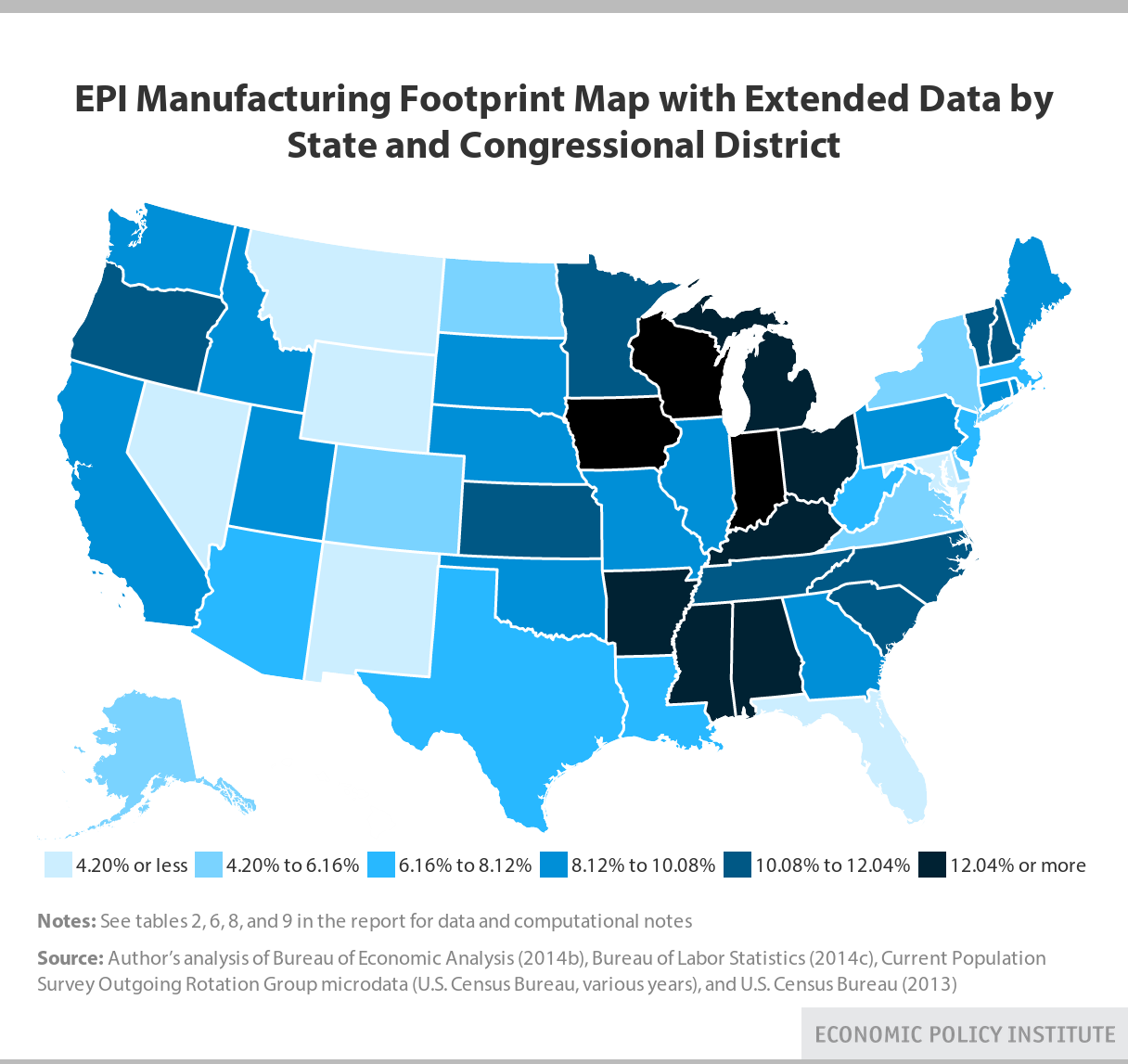

While US manufacturing has been hit hard by nearly two decades of policy failures that have damaged its international competitiveness, it remains a vital part of the U.S. economy.

The US manufacturing sector employed 12 million workers in 2013, or about 8.8 percent of total US employment. Manufacturing employs a higher share of workers without a college degree than the economy overall. On average, non-college-educated workers in manufacturing made 10.9 percent more than similar workers in the rest of the economy in 2012–2013.

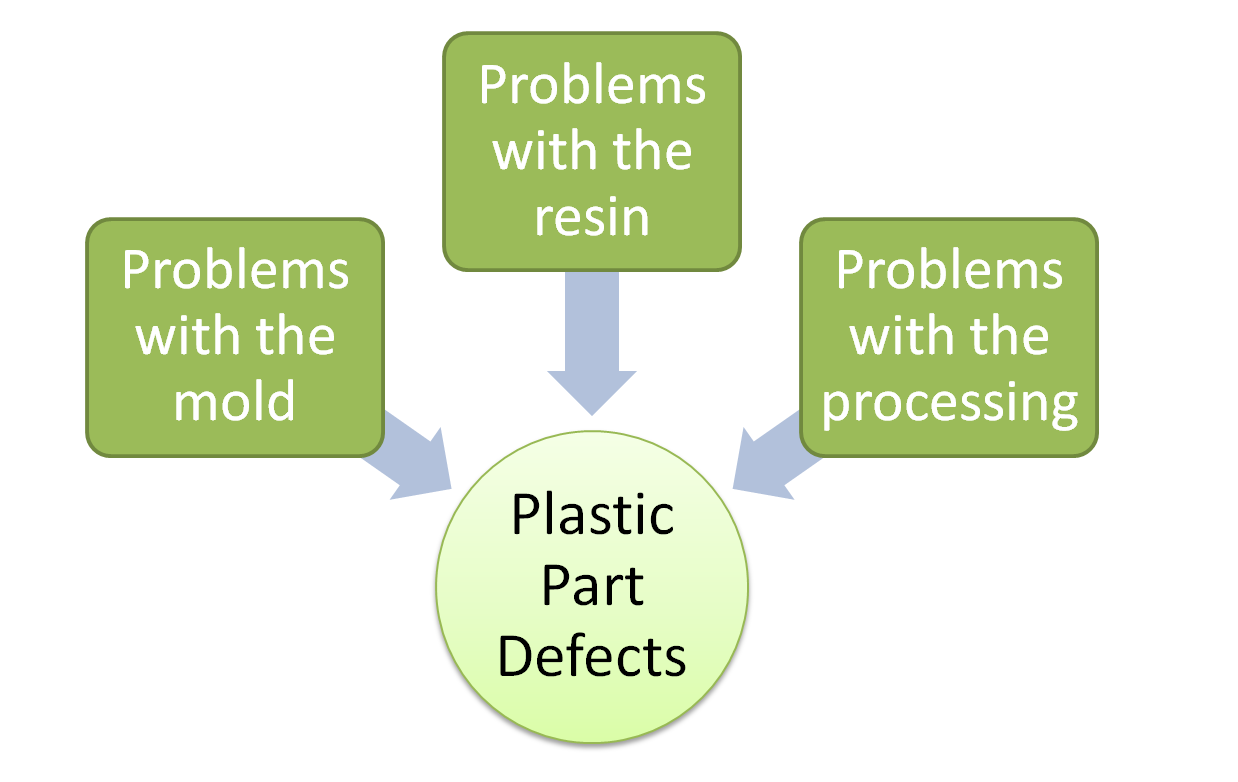

When purchasing injection molded parts, it is important to understand some of the common but scary problems and defects that impact product quality. Being familiar with these imperfections and their causes can help you work with injection molders to insure the highest quality part production is achieved.

Our eBook "An Introduction to Plastic Injection Molding" will give you lots answers. We developed this eBook with designers, engineers and purchasing specialists in mind. It is written to provide a basic understanding of plastic injection molding presses, processes and costs. Our goal is to make our customers more knowledgeable about what goes into making a plastic part. You can download your copy here.