The number of polymer compounds has grown over the past 20 years. As a result, plastics are being used in more applications than ever before. These materials are gaining a reputation for strength and endurance. Combine these improvements with the advantages of corrosion resistance and aesthetic appeal and plastics are taking center stage in the manufacturing of many consumer and industrial components. Due to their versatility, strength and light weight characteristics, plastics are taking a larger role in the transportation, medical and construction industries.

Recent Posts

The mere mention of robots taking over manufacturing sends apocalyptic terror throughout the factory. Tales of an army of zombie robots replacing workers may sell news stories, but it is far from the truth.There are many key differences between robots and zombies.

STEM and Manufacturing Careers

In the heyday of manufacturing in America, internships and apprenticeships were highly sought out job experiences. Students knew the skills they gained during an internship could help shape their future success.

Since the mid-1960’s, however, the industry and the employment picture has taken some big hits. It has only been in the past five years, that we have seen manufacturing output and jobs begin to grow again.

High schools and colleges throughout the country pay tribute to Rube Goldberg’s legacy every year though The Rube Goldberg Machine Contest. According to the contest website “The Rube Goldberg Machine Contests bring Goldberg's cartoons to life as a way of helping students transcend traditional ways of looking at problems, taking them into the intuitive chaotic realm of imagination. The resulting inventions are collections of bits and pieces, parts of now useless machines, cobbled together to achieve an innovative imaginative, yet somehow logical contraption to meet the annual contest challenge.”

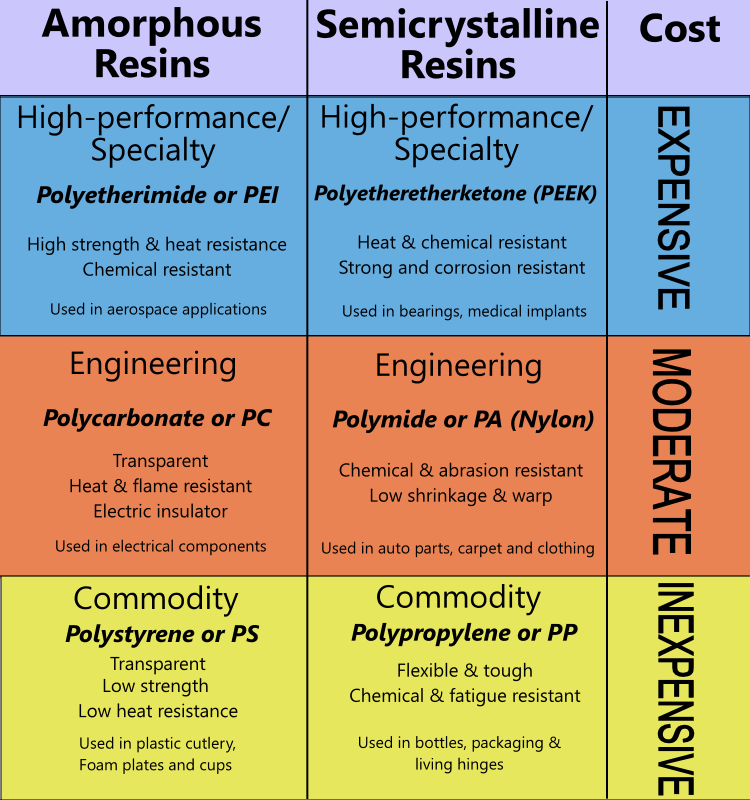

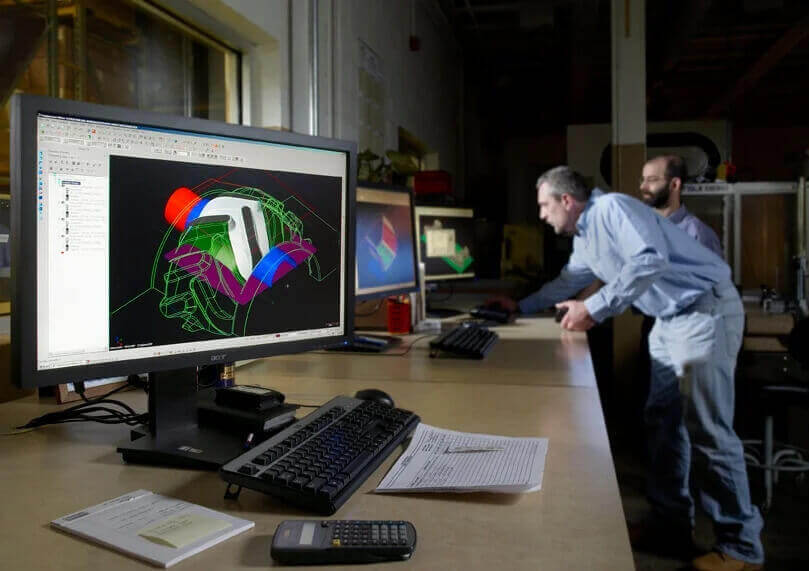

Advances in the development of new and improved polymers have led many engineers and product designers to re-think their use of more traditional materials in the manufacturing process. Parts once thought of as impossible to create using plastic, are now being designed with polymers at a higher rate than ever before.

Plastics have historically offered many advantages over other materials, particularly metal. Plastic parts are lighter and afford more design flexibility. They tend to be less expensive than metals and need little if any finishing or additional assembly. And today's innovative polymers are developed with the environment in mind. Using bio-based solutions and easily compostable materials, the goal is to leave as little impact on the planet as possible.

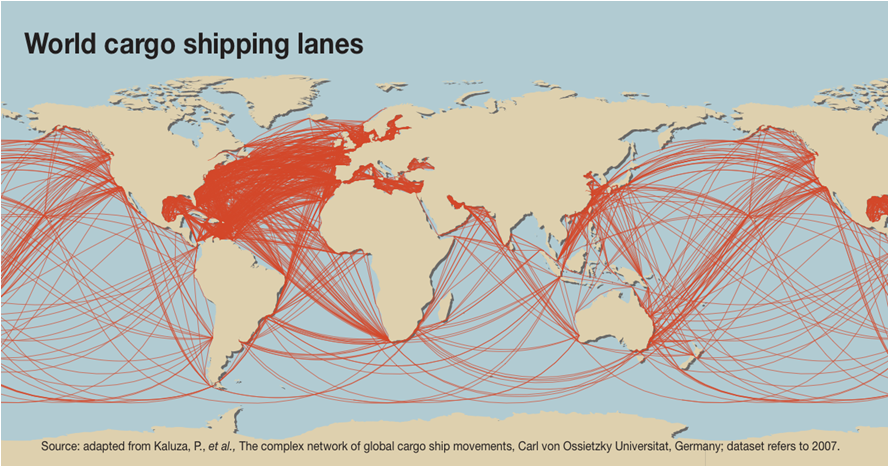

Regulatory compliance has become a focus in recent years. Products from other countries, particularly China, face additional scrutiny. From car seats to dog treats, there have been numerous safety problems.

American vs. Overseas Manufacturing

There are many risks when it comes to selecting OEM suppliers. Understanding them is essential to running a successful business. In this article, we’ll examine the factors that impact scheduling and time-to-market when using an offshore supplier.

There are many factors that impact the total cost of goods purchased. On the surface, some offshore suppliers may seem cheaper. However, the true delivered cost is impacted by many variables. Using this overview, you should be able to better compare all of your supplier choices.

American Manufacturing and Products

Once in a while, you find a video that is so well done, so compelling, that you must share. This video, from American Made Matters is a great example. It will make you think twice about where products are made; knowing that the simple act of buying American-made products can have a profound impact on our economy. It's all about creating jobs. Jobs that are secure and well-paying. Jobs that can help re-build our middle class.