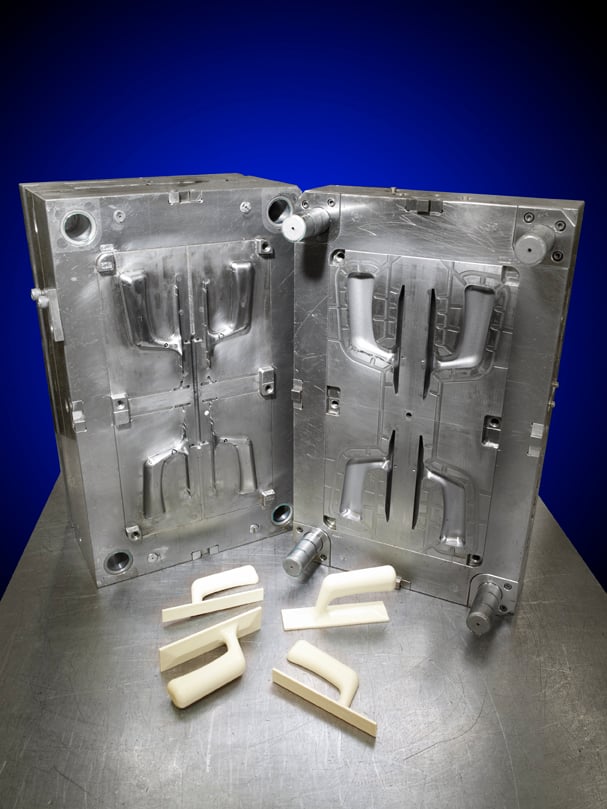

When working with any manufacturing process, a number of defects unique to that process commonly occur. This is true across many processes and industries, including injection molding and high volume injection molding.

As we have previously discussed on this blog, there are several common injecting molding defects; however, an injection molder who is vigilant about quality, like our team at The Rodon Group, will be able to manage these injection molding defects, minimizing or eliminating them all together.